SS sheet can be roughly divided into three categories: 200 series, 300 series and 400 series, of which 300 series is the most commonly used, 200 series and 400 series are a substitute for 300 series on a certain course, and strictly speaking, 400 series is not called stainless steel , Called stainless iron, because it does not contain nickel, so it can be attracted by magnets. The 200 series and 300 series have nickel, so they are non-magnetic and cannot absorb iron.

|  |

| Product Name | SS Sheet |

| Thickness | 0.25~150mm |

| Width | 600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Standard | ASTM GB/T JIS4 ASME BS DIN EN |

| Material | 310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L,302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex, etc. |

| Brand Name | TISCO, BAO STEEL, ZPSS, LISCO, POSCO, NAS |

| Technique | Hot Rolled And Cold Rolled |

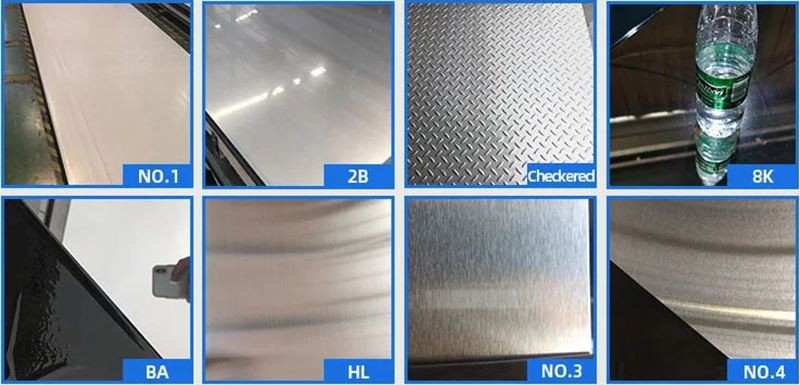

| Surface | 2B, 2D, BA, NO. 1, NO. 4, NO. 8, 8K, mirror,checkered,embossed,hair line, sand blast, Brush, etching, etc |

| Price Term | FOB, CNF, CFR, CIF, etc |

| Surface finish | Characteristics and application |

| NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy compreh ensive uses. |

| NO.1 | The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling. |

| NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150#320 on the NO.4 finish and has continuous streaks,mainly used as buildingsornaments elevators,door of building,frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

The surface of ss sheet is easy to be scratched, scratched, etc. Once scratched, the scratched surface is no longer beautiful. When we are grinding, we must protect the mirror stainless steel surface for the first time-film. In addition, the inner wall of the ss sheet packaging bag also has a plastic inner film, which has a moisture-proof effect, so in order to use it well, we must pay attention to the moisture-proof performance of the stainless steel packaging bag.

The ss sheet packed in a wooden box is usually transported by air, sea or logistics. The distance is far away. To avoid shaking caused by bumps, the wooden box can only be a little larger than the actual material. After the material is completely installed, the wooden box The sides and top are stapled and they are completely packed.

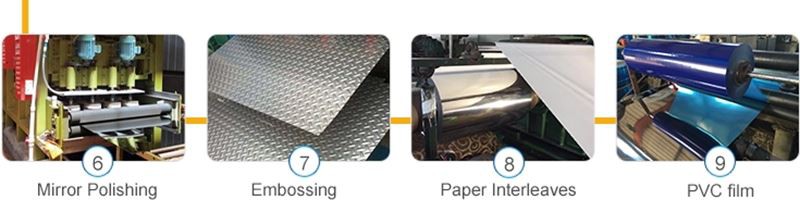

The mirror surface treatment process of the ss sheet is to polish the stainless steel surface so that the surface of the ss sheet has a mirror effect. In our ss sheet surface processing mirror surface treatment, there are different grades: 6K, 8K, super fine grinding 10K, can be processed according to different requirements.

The color ss sheet we often see is realized by the ss sheet surface processing and plating process. After processing, the color is rich. After plating, not only the appearance is more decorative, but also the wear resistance and corrosion resistance of the stainless steel ss sheet surface products.

Please Contact Us! Chloe MP/Wechat/Whatsapp:+13213178890 Email:sales@licheungsteel.com |

Hot Tags: ss sheet, manufacturers, suppliers, factory, price, for sale,