Stainless steel roll is divided into 200, 300, and 400 series from the big classification. The main difference is their nickel content. The 400 series has the highest nickel content, followed by the 300 series, and again by the 200 series. But it is not that the higher the series, the better the attributes. The strength of the attributes also depends on the structure.

| Product Name | Stainless Steel Roll |

| Length | as required |

| Width | 3mm-2000mm or as required |

| Thickness | 0.1mm-300mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 25tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit |

| Export packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

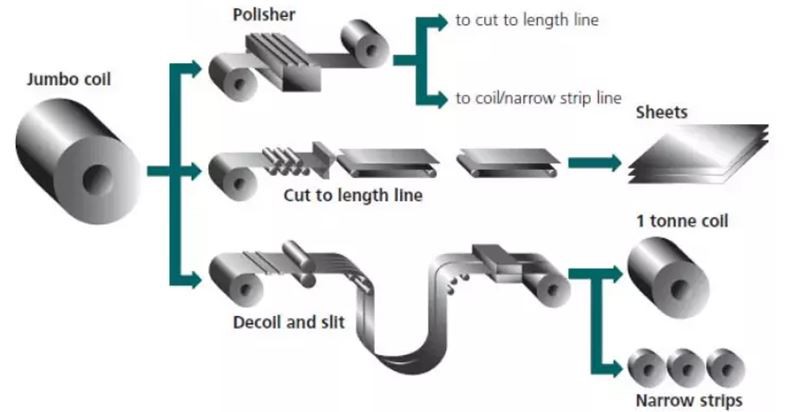

Stainless steel roll production process:

1. Stainless steel roll is a kind of high-alloy steel, which has great resistance to rolling deformation. In order to perform high-efficiency and high-precision rolling, a rigid rolling mill should be used, and a multi-roll cold rolling mill is generally used;

2. The special welding process is also a feature of stainless steel roll production;

3. In the production process of stainless steel roll, the raw material (hot rolled coil) should be annealed, the intermediate annealing during the cold rolling process, and the final product should be annealed, so annealing is an important part of production

4. stainless steel roll is a high-grade steel product, which has very strict requirements on surface quality. It not only does not allow residual metallurgical defects caused by the previous process, but also does not allow obvious defects caused by the cold rolling process;

5. The production of stainless steel roll is a joint operation of multiple units. Process balance and process management are very important. A strong production scheduling system is necessary to ensure continuous high-quality production.

Stainless steel roll is a series of iron-based alloys that contain at least about 11 percent chromium (a component that prevents iron from rusting) and are heat-resistant.Different types of stainless steel include carbon (0.03% above) greater than 1.00%), nitrogen, aluminum, silicon, sulfur, titanium, nickel, copper, selenium, niobium, and molybdenum.Certain types of stainless steel are usually represented by three digit Numbers, such as 304 stainless steel.The reason for preventing the formation of ferric oxide is the presence of chromium in the alloy. |

especially due to the tendency of exposed chromium atoms to form an "invisible and attached chrome-rich oxide film", showing further characteristics of being able to self-oxidize.- healing (reshaping after disrupting the presence of oxygen in the atmosphere).Since then, various modifications to the content of the stainless steel roll have been made to further improve corrosion resistance, including:Increase the chromium content to more than 11%;Add 8% or more nickel;As well asAdd molybdenum (it also increases resistance to "pitting"). |

Stainless steel roll packaging is a necessary process to ensure the integrity of the quantity and quality of the product. Since the packaging of the product directly affects the value and sales of the product, for most products, packaging is an indispensable condition for product transportation.

There are 2 kinds of processes for stainless steel roll packaging: one is simple packaging. After the steel coil is coiled, 1 to 3 steel strips are bundled on the outer circle for fixing. This process is suitable for hot rolled coils, cold hard coils, and stainless steel rolls with short shipping distances and good shipping conditions;The second is fine packaging. According to the requirements of packaging technology, different packaging materials are wrapped on the outer surface of stainless steel roll and bundled and shaped.

Stainless steel roll is a kind of common material.Originally used in tableware, it soon entered the chemical industry due to its corrosion resistance.Today, corrosion resistance is still very important, and there is a growing recognition that the mechanical properties of the material are steadily decreasing.Materials that are being applied to new applications almost daily.

Because the stainless steel roll high strength, flexibility and good corrosion resistance, stainless steel roll is now widely used in modern architecture.It is used for the exterior walls of large, high-impact buildings, and can also be seen indoors in the form of handrails, countertops, and backboards.

Please Contact Us! Chloe MP/Wechat/Whatsapp:+13213178890 Email:sales@licheungsteel.com |

Hot Tags: stainless steel roll, manufacturers, suppliers, factory, price, for sale,