According to RAL color card, we can produce double-sided monochrome and color coated steel coil color coated coil. About color steel roll, we have five color plate production line, can cover and segmentation, can also produce printed and embossed, look forward to establishing a good long-term relationship with you.

Color Coated Steel Coil Characteristic Performance

Color coated steel coil product obtained by subjecting a cold-rolled steel plate or a galvanized steel sheet to a surface chemical treatment (roll coating) or a composite organic film (such as a PVC film) and then baking and curing. Some people call this product "pre-rolled color steel plate" and "plastic color steel plate". Color plate products are produced by the manufacturer on a continuous production line, so it is also called color coated steel coil. The color steel plate not only has the mechanical strength of the steel material, the easy forming property, but also the good decorative and corrosion resistance of the coating material.

Color coated steel coil movable room has the advantages of light weight, high strength, heat insulation, beautiful appearance and durability, and is a high-grade building installation which is integrated with architecture and decoration. Color steel plate movable room construction is clean, widely used in large-span factory buildings, warehouses, office buildings, villas, roof tops, air purification rooms, cold storage, shops, kiosks and temporary houses. Lightweight steel sandwich panels with a square weight of less than 14KG can fully reduce the structural load and reduce the structural cost of the mobile home.

Durable

A variety of studies have shown that it has been widely used in foreign countries for more than 40 years. The shelf life of color-coated steel plates treated with special coatings is 10-15 years. After that, anti-corrosion coatings are sprayed every 10 years. The life of movable houses can reach more than 35 years.

Thermal insulation

The heat insulating materials commonly used in the color steel plate composite board are: rock wool, glass fiber cotton, polystyrene (EPS), polyurethane, etc., and the thermal conductivity is low, so that the movable room has good thermal insulation effect. The high-strength color steel plate is made of high-strength steel plate (tensile strength 5600kg/cm) plus the most advanced design and roll forming. Therefore, the color steel plate movable room has excellent structural characteristics.

Color Coated Steel Coil Constitute Application

1.The color steel cold rolled substrate may be divided into a substrate, hot dip galvanized and electro-galvanized base substrate.

2.The coating type of color steel plate can be divided into: polyester, silicon modified polyester, partial polyvinylidene fluoride, plastisol.

3.can be divided into color plate color orange, butter yellow, deep sky blue, navy blue, blush, red brick according to user requirements, ivory, porcelain blue and other types.

4.The surface condition of color steel plate can be divided into coated plate, embossed plate and printed plate.

5.The use of painted steel market is divided into three parts: construction, household appliances and transport. Among them, the construction industry the largest proportion, followed by household appliances industry, while transportation accounts for only a small proportion.

Color coated steel coil for construction is usually made of hot-dip galvanized steel sheet and hot-dip aluminum-zinc steel sheet. They are mainly processed into strip of corrugated board or polyurethane composite panels for the construction of industrial buildings and airports, airports, warehouses, freezers and so on. Building roofs, walls and doors.

Household appliances color plates are usually based on galvanized sheet and cold, for large-scale production of refrigerators and air conditioning systems, refrigeration machine, toaster and furniture.

Transportation industry usually galvanized and cold plate as the substrate, and mainly used for automotive interior parts and the oil pan.

Product Process

Main production process of Color coated steel coil

The crane is used to place the raw material coil on the processing platform of the color coating unit, and the transport truck transports the steel coil to the coil seat in front of the color coating unit. After removing the strap, the raw material into a coil uncoiler, belt guide means will automatically be guided to the coil head to cut the head of the cutting position, then the upper sewing machine with the loops stitched into the cleaning zone first coil washed and then dried by hot air, into the electroless plating machine, coated with a layer of chromium on the surface of the aqueous color coating steel coils, hot-air dryer into the drying machine from electroless plating, and then the steering roller by a thin coating into the coater fine and then drying the coating into the curing oven.

Production Show

Color coated steel coil is color coated galvanized steel, also known as pre-coated steel, PPGI, etc. Color coated steel coil takes hot dip galvanized steel coil as the base material, first carries on the surface pretreatment, then carries on the coating of one or more layers through the roller coating for the liquid coating, and finally carries on the baking and cooling.The coatings used include polyester, silicon modified polyester, high durability, corrosion resistance and formability.

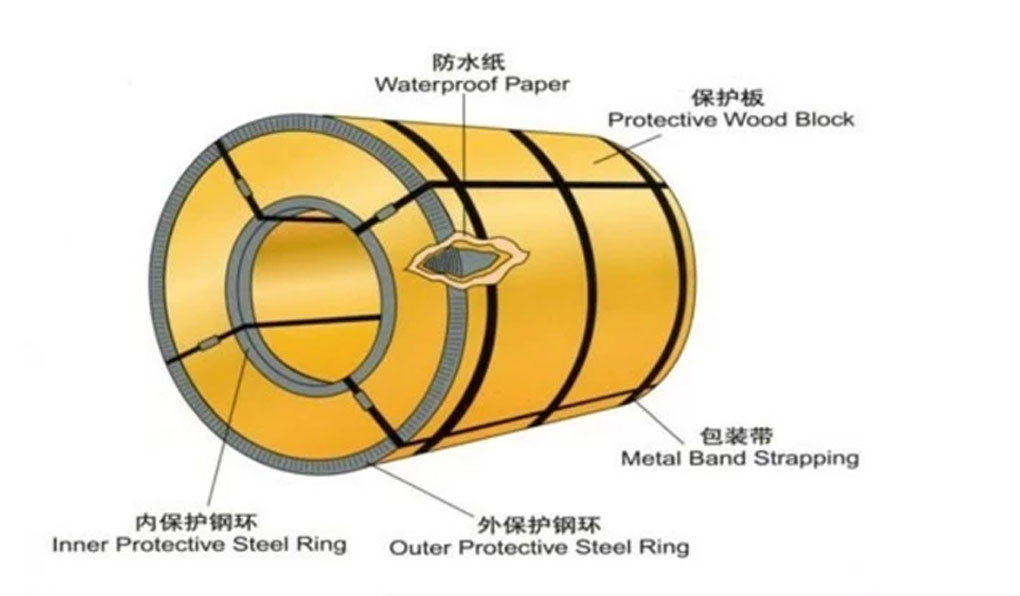

Packing and Shippping

Mill standard export seaworthy package with inner sleeve and with 4 eye bands 3 circumferential bands in steel,galvanized metal fluted rings on iner and outer edges,glavanized metal and water proof paper wallprotection disk around circumferences.

Our Workshop

We are professional manufacturer ppgi Coil, the company has five production lines, two cutting lines and international advanced laminating machine, the annual output of each production line of 150,000 tons, all production are based on national standards and relevant industry standards, our PPGI and PPGL can be embossed, printed and heated on aluminum zinc galvanized and hot dip galvanized sheet. On the basis of equality and mutual benefit, win-win, our company carried out extensive exchanges and friendly cooperation with domestic and foreign companies.

Contact us

Chloe

Sales Manager

Tel:+86 371 89812229/Fax:+86 371 89812228

MP/Wechat/Whatsapp:+86 13213178890

E-mail:sales@licheungsteel.com

Hot Tags: color coated steel coil, manufacturers, suppliers, factory, price, for sale, prepainted galvanized steel coil, pre painted steel, color steel coil, coated steel coil, prepainted steel coil, colour coated coil