In order to further understand the corrosion resistance of the painted coil, make the surface zinc layer not directly contact with the air, and increase the surface color, it is necessary to apply paint.That is, according to the main use of different, must choose the appropriate substrate and building coatings, using the appropriate method of painting, in order to produce a prescribed color coating roll.Color Coated Zinc Aluminium Steel Coil

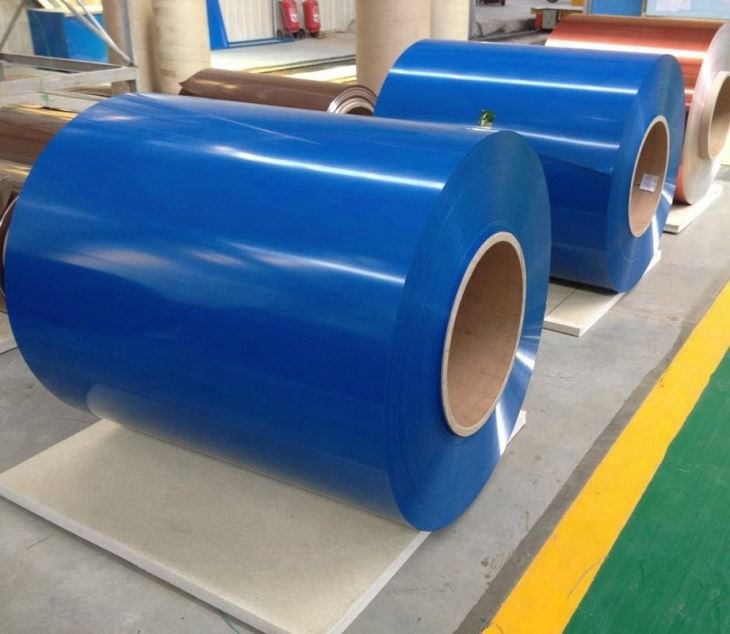

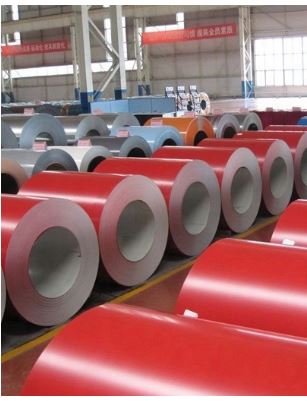

Product Display

Color Coated Zinc Aluminium Steel Coil Characteristic Performance

Color Coated Zinc Aluminium Steel Coil coating is a product obtained by subjecting a cold-rolled steel plate or a galvanized steel sheet to a surface chemical treatment (roll coating) or a composite organic film (such as a PVC film) and then baking and curing. Some people call this product "pre-rolled color steel plate" and "plastic color steel plate". Color plate products are produced by the manufacturer on a continuous production line, so it is also called color coated steel coil. The color steel plate not only has the mechanical strength of the steel material, the easy forming property, but also the good decorative and corrosion resistance of the coating material. Color steel plates are emerging materials that are highly respected in the world today. With the advancement of science and technology, the enhancement of environmental awareness, and the improvement of people's living standards, color steel plate activity rooms have increasingly shown strong vitality and broad market prospects, and are subject to construction, home appliances, electromechanical, transportation, interior decoration, and office equipment. And the favor of other industries.

Color Coated Zinc Aluminium Steel Coil movable room has the advantages of light weight, high strength, heat insulation, beautiful appearance and durability, and is a high-grade building installation which is integrated with architecture and decoration. Color steel plate movable room construction is clean, widely used in large-span factory buildings, warehouses, office buildings, villas, roof tops, air purification rooms, cold storage, shops, kiosks and temporary houses. Lightweight steel sandwich panels with a square weight of less than 14KG can fully reduce the structural load and reduce the structural cost of the mobile home.

Easy Installation

Color Coated Zinc Aluminium Steel Coil movable room has the characteristics of light weight, splicing installation and free cutting, which determines the simplicity of installation of the movable room, which can greatly improve the efficiency and save the construction period. The surface material and insulation material of the fire-proof color steel sandwich panel are non-combustible materials, which can fully meet the fire protection specifications of the movable room.

Durable

A variety of studies have shown that it has been widely used in foreign countries for more than 40 years. The shelf life of color-coated steel plates treated with special coatings is 10-15 years. After that, anti-corrosion coatings are sprayed every 10 years. The life of movable houses can reach more than 35 years.

Beautiful

The clear lines of the pressed color coated zinc aluminium steel coils have dozens of colors, which can meet the needs of any style movable room building and achieve satisfactory results.

Thermal Insulation

The heat insulating materials commonly used in the color steel plate composite board are: rock wool, glass fiber cotton, polystyrene (EPS), polyurethane, etc., and the thermal conductivity is low, so that the movable room has good thermal insulation effect. The high-strength color steel plate is made of high-strength steel plate (tensile strength 5600kg/cm) plus the most advanced design and roll forming. Therefore, the color steel plate movable room has excellent structural characteristics.

In order to make the building coating and galvanized steel plate have good adhesion, the hot dip galvanized surface needs to be treated with organic chemistry.First, the adhesion on the surface of galvanized steel and dirt clean, otherwise it will affect the adhesion force of the coating, so it is necessary to deoiling and cleaning.Organic chemical conversion treatments are then carried out, usually by creating layers of complex compounds on the hot dip galvanized surface, or by phosphate treatment.The former has good adhesion and the latter has good corrosion resistance.Organic chemical conversion treatment should be fully dry, can contain moisture in the body

under the state of painting.Color Coated Zinc Aluminium Steel Coil

Packing

Our Company

Our annual capacity of color coating line is about 600,000 tons, hot-dip galvanized/galvanized steel coil is 0.12-1.5 * 650-1250 mm;The capacity of galvanized steel coils (0.2-1.2 * 750-1250 mm) and galvanized steel coils (0.2-0.8 * 750-1250 mm) is about 300,000 tons. Our company is fully aware of the importance of quality and has the strictest quality control system.Our products have high precision and high quality, not only with excellent decorative, molding and corrosion resistance, but also with high paint adhesion, can keep bright and beautiful colors for a long time.

Contact us

Chloe

Sales Manager

Henan Li Cheung Steel Co., Ltd

Address: DEVELOPMENT ZONE HUIGUO TOWN, ZHENGZHOU CHINA

Tel:+86 371 89812229 Fax:+86 371 89812228

MP: +86 13213178890 Wechat/Whatsapp: + 86 13213178890

E-mail: sales@licheungsteel.com

Website: www.jianhuissteel.com

Hot Tags: color coated zinc aluminium steel coil, manufacturers, suppliers, factory, price, for sale,