50 Most Frequently Asked Questions on GI Roofing Sheet

Certainly! Here are answers to 50 frequently asked questions about Galvanized GI roofing sheets:

A GI roofing sheet is a roofing material made from galvanized iron (GI) steel, which is coated with a layer of zinc to prevent corrosion. The term "galvanized" refers to the process of coating iron or steel with a protective layer of zinc to prevent rust and corrosion. Galvanized GI roofing sheets are commonly used in construction for their durability, weather resistance, and cost-effectiveness. They are available in various thicknesses and profiles to suit different roofing needs.

|

Product Name |

GI Roofing sheet |

|

Material |

Galvanized steel or Galvalume steel |

|

Width |

600mm-1500mm, according to the customer's requirement |

|

Weight per Bundle |

2-4tons |

|

20' container weight |

25-28tons (unless there is limited weight at the destination port) |

|

Logo |

Printed according to your design |

| Other shapes |

T shape or other corrugated to choose |

|

Price |

Welcome to send me your requirements, and we will quote the lowest FOB/CFR/CIF price to you. |

|

Applications range |

from home appliances, building materials, machinery, roofing sheets, etc. |

Which Galvanized GI Roofing sheet material lasts the longest?

In general, thicker zinc coatings tend to provide better protection against corrosion and help extend the service life of roof panels. The service life of galvanized GI (galvanized iron) roofing sheets depends on a number of factors, including the quality of the material, the thickness of the zinc coating, and the environmental conditions in which they are placed.

Additionally, the specific type of galvanized GI roofing sheet can affect its durability and longevity. For example, galvanized steel roofing sheets typically have a longer service life compared to galvanized iron sheets due to the inherent strength and corrosion resistance of steel.

Other factors that may affect the longevity of galvanized GI roofing panels include proper installation, regular maintenance, and harsh weather conditions in the area of installation.

In summary, galvanized steel roofing sheets with a thicker zinc coating are generally considered to have the longest service life, especially when properly installed and maintained.

2. What are the Benefits of a Galvanized GI roofing sheet?

GI roofing sheets are used to provide a durable and weather-resistant roofing solution for various structures.

The benefits of galvanized GI roofing sheets include:

GI roofing sheets are highly durable and can withstand various weather conditions, including heavy rain, strong winds, and extreme temperatures.

The galvanized coating on GI roofing sheets provides excellent corrosion resistance, preventing rust and extending the lifespan of the roofing material.

GI roofing sheets require minimal maintenance, reducing the need for frequent repairs and upkeep.

Compared to other roofing materials, GI roofing sheets are cost-effective, making them a popular choice for both residential and commercial construction projects.

GI roofing sheets are available in various thicknesses and profiles, making them suitable for a wide range of roofing applications.

Despite their durability, GI roofing sheets are lightweight, which makes them easier to handle and install compared to heavier roofing materials.

GI roofing sheets can be coated with reflective materials to improve energy efficiency by reducing heat absorption and lowering cooling costs in warmer climates.

When properly installed, GI roofing sheets can provide a degree of fire resistance, enhancing overall safety in buildings.

GI roofing sheets are recyclable, contributing to sustainability efforts in construction projects.

Overall, the benefits of galvanized GI roofing sheets make them a practical and cost-effective choice for various roofing applications.

Yes, GI roofing sheets are designed to be weather-resistant, capable of withstanding harsh environmental conditions.

The galvanized coating on these sheets provides excellent protection against various weather conditions, including rain, snow, wind, and sunlight. This coating acts as a barrier, preventing moisture from penetrating the sheet and causing corrosion. As a result, GI roofing sheets are known for their durability and ability to withstand harsh environmental elements, making them suitable for use in different climates and regions.

GI roofing sheets are typically installed by fastening them to the underlying structure using screws or nails.

The installation process for GI (Galvanized Iron) roofing sheets typically involves the following steps:

Measure the dimensions of the roof and cut the GI roofing sheets to size using appropriate tools such as tin snips or a metal-cutting saw.

Start laying the GI roofing sheets from the bottom edge of the roof, working upwards. Overlap each sheet with the previous one to ensure proper water drainage. Use roofing screws or nails to secure the sheets to the roof structure, making sure to fasten them securely but not overtighten, as this could damage the sheets.

Install ridge caps, flashing, and other necessary accessories to seal joints, corners, and edges. These accessories help to enhance the weatherproofing and aesthetics of the roof.

Seal the exposed fasteners and seams with appropriate sealant or silicone to prevent water infiltration. Ensure that all edges and joints are properly sealed to enhance the waterproofing of the roof.

Once the installation is complete, inspect the roof for any gaps, loose fasteners, or other issues that may compromise the integrity of the roofing system. Make any necessary adjustments or repairs as needed.

Remove any leftover debris, tools, and materials from the roof and surrounding area to ensure a clean and safe work environment.

It's essential to follow manufacturer guidelines and local building codes during the installation process to ensure the proper installation and performance of GI roofing sheets. Additionally, if you're not experienced with roofing installation, it may be advisable to seek professional help to ensure the job is done correctly.

Yes, GI roofing sheets are versatile and can be used for both residential and commercial buildings.

6. Are GI roofing sheet lightweight?

Yes, compared to some other roofing materials, GI roofing sheets are relatively lightweight.

Advantages include durability, corrosion resistance, affordability, and ease of installation.

8. Do GI roofing sheet require maintenance?

They require minimal maintenance, as the zinc coating helps prevent rusting.

9. Can GI roofing sheet be painted?

Yes, GI roofing sheets can be painted to achieve the desired color or appearance.

GI roofing sheets are not inherently fire-resistant, but their steel base material has some fire-resistant properties.

The lifespan can vary, but with proper maintenance, GI roofing sheets can last around 20-30 years or more.

12. Are GI roofing sheet eco-friendly?

GI roofing sheets are recyclable, which can contribute to their eco-friendliness.

Yes, the zinc coating on GI roofing sheets helps protect against saltwater corrosion, making them suitable for coastal areas.

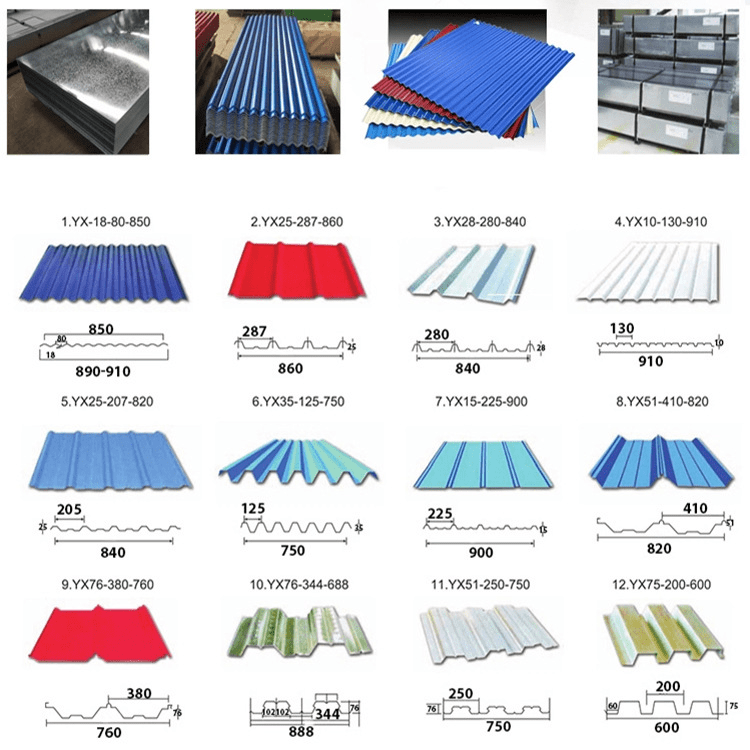

Yes, GI roofing sheets are available in various profiles such as corrugated, trapezoidal, and more.

15. Are GI roofing sheet prone to denting?

They can be susceptible to denting if impacted with sufficient force.

GI roofing sheets have a zinc coating that provides better corrosion resistance compared to ordinary steel sheets.

Yes, GI roofing sheets are commonly used in industrial applications due to their durability.

GI roofing sheets can reflect sunlight, helping to reduce heat absorption and potentially contributing to energy efficiency.

19. Can I install GI roofing sheet myself?

DIY installation is possible, but it's recommended to have professional help for proper installation.

20. Do GI roofing sheet come with warranties?

Some manufacturers offer warranties on their GI roofing sheets; it's best to inquire about this before purchase.

GI roofing sheets are generally more affordable than materials like tile or slate.

Yes, they can be used as a base for solar panel installations.

23. Are GI roofing sheet noisy during rainfall?

GI roofing sheets can produce some noise during heavy rainfall, but insulation and design modifications can help reduce this.

24. How do I clean GI roofing sheets?

Cleaning with water and a mild detergent is usually sufficient to maintain their appearance.

The installation process for GI (Galvanized Iron) roofing sheets typically involves the following steps:

Ensure that the roof structure is properly prepared and cleaned. Remove any existing roofing material, debris, and protruding nails or screws.

Measure the dimensions of the roof and cut the GI roofing sheets to size using appropriate tools such as tin snips or a metal-cutting saw.

Start laying the GI roofing sheets from the bottom edge of the roof, working upwards. Overlap each sheet with the previous one to ensure proper water drainage. Use roofing screws or nails to secure the sheets to the roof structure, making sure to fasten them securely but not overtighten, as this could damage the sheets.

Install ridge caps, flashing, and other necessary accessories to seal joints, corners, and edges. These accessories help to enhance the weatherproofing and aesthetics of the roof.

Seal the exposed fasteners and seams with appropriate sealant or silicone to prevent water infiltration. Ensure that all edges and joints are properly sealed to enhance the waterproofing of the roof.

Once the installation is complete, inspect the roof for any gaps, loose fasteners, or other issues that may compromise the integrity of the roofing system. Make any necessary adjustments or repairs as needed.

Remove any leftover debris, tools, and materials from the roof and surrounding area to ensure a clean and safe work environment.

It's essential to follow manufacturer guidelines and local building codes during the installation process to ensure the proper installation and performance of GI roofing sheets. Additionally, if you're not experienced with roofing installation, it may be advisable to seek professional help to ensure the job is done correctly.

Yes, they are recyclable and can be melted down and reused.

26. Are GI roofing sheet resistant to pests?

They are not entirely pest-proof, but their steel composition can discourage pests like rodents from damaging them.

Yes, some GI roofing sheets are designed to be flexible enough to accommodate curved roofs.

28. Do GI roofing sheet require insulation?

Insulation is recommended to regulate indoor temperatures and minimize condensation.

Yes, they can be custom ordered in various colors and sizes.

30. Can GI roofing sheet be used with rainwater harvesting systems?

Yes, GI roofing sheets are compatible with rainwater harvesting setups.

While they offer some resistance, extremely large hailstones can potentially cause damage.

Walking on them is possible, but it's best to avoid excessive foot traffic to prevent damage.

33. Do GI roofing sheet expand and contract with temperature changes?

Yes, like any metal, GI roofing sheets can expand and contract with temperature fluctuations.

34. Can I install solar reflectors on GI roofing sheet?

Solar reflectors can be installed on GI roofing sheets to enhance energy efficiency.

Periodic cleaning and inspection for damage or rust spots are the main maintenance tasks.

36. Can GI roofing sheet be used in areas with heavy snowfall?

Yes, but proper structural support is crucial to handle the weight of accumulated snow.

37. Do GI roofing sheet have good wind resistance?

When properly installed, GI roofing sheets can withstand moderate to high wind speeds.

38. Are GI roofing sheet prone to rusting over time?

The zinc coating on GI roofing sheets provides protection against rusting, but maintenance is still important to prevent corrosion.

Yes, they can be used for both types of roofs, but the pitch affects their installation.

40. Do GI roofing sheet require ventilation?

Proper ventilation is recommended to prevent moisture buildup beneath the sheets.

Yes, manufacturers often provide installation guidelines that should be followed for optimal performance.

Yes, they can be integrated with gutters and downspouts for efficient water drainage.

While they are not specifically designed for seismic resistance, their attachment to a well-engineered structure can contribute to overall resilience.

44. Can GI roofing sheet be used for agricultural buildings?

Yes, they are commonly used for agricultural structures like barns and sheds.

The process involves coating iron or steel sheets with zinc through a hot-dip galvanization process.

The process of manufacturing GI (Galvanized Iron) roofing sheets typically involves the following steps:

The steel coils undergo a cleaning process to remove any surface contaminants such as oil, grease, or rust. This is typically done using chemical cleaning agents or mechanical cleaning methods such as shot blasting.

The cleaned steel coils are then immersed in a bath of molten zinc at high temperatures. This process, known as hot-dip galvanizing, forms a protective zinc coating on the surface of the steel, which helps prevent corrosion and rusting.

After galvanizing, the coated steel coils are cooled in a controlled environment to solidify the zinc coating. The coils are then inspected for any defects or irregularities in the coating.

The coated steel coils are passed through roll-forming machines, where they are shaped and profiled into the desired dimensions and profiles of GI roofing sheets. This process involves passing the coils through a series of rollers that gradually bend and shape the metal into the required profile.

Once the profiling is complete, the GI roofing sheets are cut to the desired length using cutting and shearing machines. This step ensures that the sheets are uniform in size and ready for packaging and transportation.

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the GI roofing sheets meet the required standards for thickness, coating thickness, profile accuracy, and overall quality.

The finished GI roofing sheets are packaged and labeled according to customer specifications and requirements. They are then shipped to distribution centers or directly to construction sites for installation.

Overall, the manufacturing process of GI roofing sheets involves several precise steps to ensure the production of high-quality, durable roofing materials suitable for various construction applications.

Installing over existing materials might be possible, but it's important to assess the structural integrity and seek professional advice.

The zinc coating serves as an anti-corrosion treatment, but additional measures can be taken in harsh environments.

They can be used, but structural engineering considerations are important for seismic safety.

They are generally resistant to mild chemical exposure, but prolonged exposure to aggressive chemicals can lead to corrosion.

50. Can I install insulation on top of GI roofing sheets for better energy efficiency?

Insulation can be installed beneath the roofing sheets for more effective thermal regulation.

Installing insulation on top of GI (Galvanized Iron) roof panels can significantly improve energy efficiency by reducing heat transfer and improving thermal insulation. Here's how you can do it:

Select an appropriate insulation material based on factors such as R-value (thermal resistance), compatibility with the roof structure, and local building codes. Common insulation materials for roofs include foam board, fiberglass batts, and spray foam insulation.

Ensure that the GI roof panels are clean and free of any debris, dust, or contaminants that could affect the adhesion of the insulation. Repair any damaged areas or leaks before proceeding.

Depending on the climate and local building codes, you may need to install a vapor barrier between the GI roof panels and the insulation to prevent moisture buildup and condensation. This barrier is typically a plastic sheet or membrane installed on the warm side of the insulation.

Measure the dimensions of the roof panels and cut the insulation panels to fit snugly on top of them. Use a sharp utility knife or insulation saw to cut the panels accurately.

Place the insulation panels on top of the GI roof panels, ensuring they cover the entire surface area without gaps or overlaps. Use appropriate fasteners such as screws or adhesive to secure the insulation panels in place. Follow manufacturer recommendations for spacing and fastening methods.

Seal any joints, edges, or gaps between the insulation panels using foam sealant or tape to prevent air leakage and improve the insulation's effectiveness.

Depending on the insulation material used, you may need to install a roofing membrane or protective layer on top of the insulation to provide additional weatherproofing and UV protection.

Once the insulation is installed and secured, you can proceed with installing roofing materials such as metal sheets, shingles, or tiles over the insulation to complete the roof assembly.

By installing insulation on top of GI roof panels, you can create a more energy-efficient and comfortable indoor environment while reducing heating and cooling costs.

Please note that the information provided here is general in nature and may vary based on specific products and manufacturers. Always refer to manufacturer guidelines and consult with professionals for accurate and up-to-date information regarding GI roofing sheets.

Q1: How many countries have you already exported?

Since its inception in 2005, Li Cheung Steel Factory has grown to become the largest manufacturer of GI PPGI steel in China. An ISO 9001-certified company.

Professional team

29,000+ experts worldwide

Senior project managers effectively control all aspects of the project

7x24 hours delivery

Located in 27 cities around the world, with 50 delivery centers, providing 200+ languages, and 7x24 hours delivery capacity, is the best partner for enterprise globalization

𝗪𝗵𝘆 I am 𝗮 𝗪𝗼𝗿𝗸𝗮𝗵𝗼𝗹𝗶𝗰?

Why I am a workaholic is not well understood. I do feel that in this GI, PPGI, GL, and Roofing Sheet job customers give me great trust, and I have the opportunity to serve as 1 service provider. What I gain is the trust of everyone. You see so many steel factories, and still, many people come to Li Cheung Steel Factory, I want to cherish this opportunity to bring value and service to customers.

Now I am 28 years old. I have gone this job for 4 years and believe I am quite experienced. To serve our clients better and get trusted, I spend a lot of time learning from our engineers and technical team. Quality is the true reason that we have survived in the market for so many years.

I am a very very enthusiastic person and I am very very glad to help you if I have any chance. If you have GI, PPGI, GL, PPGL, Roofing sheet steel industry confusion, or If you have steel internet marketing questions, or 2024 a direction, or you have ideas to make investments in 2024, or you are making adjustments, you're not quite clear, welcome to come to Li Cheung Steel Bella for advice as soon as possible.

If you need steel welcome to contact us!

Email: sales@licheungsteel.com

WhatsApp:+86 132 1317 8890

http://wa.me/8613213178890