1.What Is The Full Form Of The PPGI Steel Coil?

2. What is the PPGI steel coil specification?

3. What Is The PPGI Steel Sheet Price?

4. What Is PPGI Roofing Sheet Color?

5. What Is Coil Coating Process?

6. How Thick Is The PPGI Sheet In Mm?

7. What is the price of PPGI color-coated coil?

8. Which Is Better PPGI Or PPGL?

9. How Long Does Paint Galvanized Steel Last?

10. What are the advantages of pre-painted steel?

11. Is Painting Or Galvanizing Better?

12. How do you treat galvanized steel before painting?

13. What Paint Is Best For Galvanized Steel Before Painting?

14. What Are PPGI's Different Types Of Coating?

15. How Long To Leave Galvanized Steel Before Painting?

16. What Are The PPGI Steel Coils Technical Details In Chinese Manufacturers?

17. Is PPGI Steel Wire Fireproof?

18. What Is The HS Code For PPGI Steel?

19. Does PPGI Have Export Tax Rebates In China?

20. What Are Li Cheung Steel PPGI Steel's Advantages?

The full form of PPGI steel coil is a "Pre-Painted Galvanized Iron" steel coil.

It refers to a type of steel coil that has been coated with a layer of paint or other protective material before being formed into various products. This coating provides corrosion resistance and enhances the aesthetic appearance of the steel. PPGI is commonly used in construction, automotive, and other industries where durable and visually appealing materials are required.

The following table introduces you to the specifications of PPGI steel coil

|

Item |

Prepainted Galvanized Steel (Prepainted galvanized coil) |

|

Substrate |

GI (galvanized iron) |

|

Thickness |

0.1 mm -3.0 mm |

|

Width |

600 mm -1,250 mm |

|

Length |

Upon your requirements |

|

Coatings |

PE, SMP, HDP, PVDF |

|

Colors |

As per RAL Color (custom patterns are available) |

|

Monthly Production |

5,000-10,000 tons |

|

Package |

Standard Export Package |

PPGI steel coil specifications can vary depending on the manufacturer and specific product line. However, here are some common specifications you might find:

1) pPGI steel Material

PPGI coils are typically made from hot-dip galvanized steel or galvalume steel. The base metal provides the strength and corrosion resistance.

2) pPGI steel Material

Coating Type

PPGI stands for Pre-Painted Galvanized Iron, indicating that the steel has been coated with a layer of paint or protective coating. The type of coating can vary, including polyester(PE), silicon-modified polyester (SMP), polyvinylidene fluoride (PVDF), and high-durability polyester (HDP).

3) pPGI steel Coating Thickness

This refers to the thickness of the paint or protective coating applied to the steel. It is usually specified in micrometers (µm).

4)pPGI steel Top Coat Thickness

In a PPGI coil, there are typically multiple layers of coatings. The top coat is the outermost layer, which provides additional protection and determines the final appearance of the product.

5) Back Coat Thickness

This is the coating on the reverse side of the coil. It provides added protection and can also influence the adhesion of the coating to the base metal.

6) PPGI Steel Width

This is the width of the PPGI coil, typically measured in millimeters (mm) or inches (in).

7) Coil Weight

This is the weight of the entire coil, including both the steel and the coating. It is usually specified in kg or ton.

8) PPGI Steel Paint System

This refers to the combination of coatings used in the PPGI coil. It includes information about the type of primer, topcoat, and backcoat used.

9)PPGI Steel Tensile Strength

This is a measure of how much force the steel can withstand before it starts to deform. It is usually specified in megapascals (MPa) or pounds per square inch (psi).

10)PPGI steel Yield Strength

This is the amount of stress at which the steel begins to deform plastically. It is also specified in megapascals (MPa) or pounds per square inch (psi).

11) PPGI steel Application

PPGI coils can be designed for specific applications, such as roofing, siding, automotive parts, appliances, etc.

Remember, it's crucial to consult the manufacturer's specifications for precise details as they may vary between different products and brands.

The price of a PPGI (Pre-Painted Galvanized Iron) sheet can vary widely depending on several factors including:

Thicker sheets generally cost more than thinner ones.

Different coatings (e.g., polyester, SMP, PVDF) and their respective thicknesses will affect the price.

Larger sheets will typically cost more than smaller ones.

4)PPGI Steel Quality and Brand

Reputable brands or higher-quality sheets may come at a premium.

Prices can fluctuate due to supply and demand, as well as global market trends.

Any additional treatments or customization may also impact the price.

7) PPGI Steel Quantity

Bulk purchases may come with discounts.

Prices can vary by region or country due to factors like transportation costs and local market conditions.

The latest FOB price of PPGI per ton in 2024 is around USD 600 - USD 800.

If you have any other questions, please!

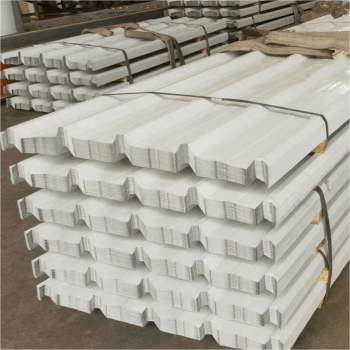

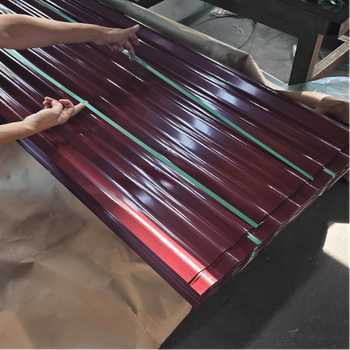

PPGI (Pre-Painted Galvanized Iron) roofing sheets come in a wide range of colors. The specific colors available can vary depending on the manufacturer and product line. Common colors for PPGI roofing sheets include:

1) PPGI Steel Standard Colors

These are typically neutral colors like white, grey, black, and beige.

These are natural and muted colors such as brown, green, and tan.

Some PPGI sheets are available in more vibrant and bold colors like red, blue, and yellow.

4) Metallic Finishes

Some manufacturers offer PPGI sheets with metallic or pearlescent finishes for a unique look.

Remember, the availability of colors may vary depending on the manufacturer and product line, so it's best to consult with the specific supplier or manufacturer for the full range of color options they offer.

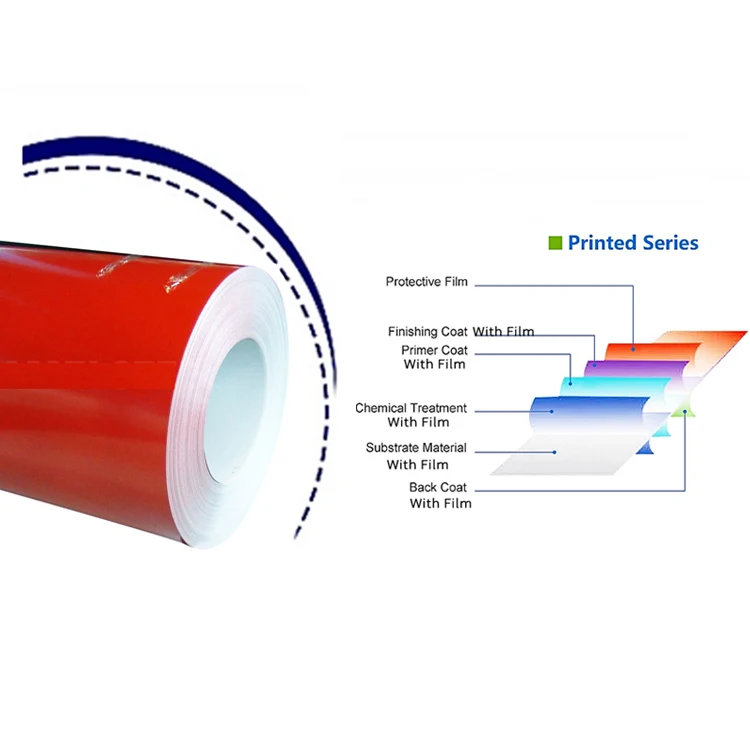

The coating process for PPGI (Pre-Painted Galvanized Iron) steel coils involves several key steps to prepare and apply the protective and decorative coatings:

- Cleaning: The galvanized steel surface is thoroughly cleaned to remove any dirt, grease, or contaminants. This is typically done using a combination of alkaline or acidic cleaners.

- Rinsing: After cleaning, the surface is rinsed to ensure all residues are removed.

- Phosphating or Chromating: The steel is treated with a solution containing phosphate or chromate compounds. This forms a thin, chemical-conversion coating on the surface. This step enhances adhesion and provides additional corrosion resistance.

- A primer coat is applied to the prepared surface. This primer is specifically designed for use on galvanized steel and provides adhesion for the subsequent layers of coating.

- The top coat, which contains pigments for color and additional protective elements, is applied. Different types of coatings (polyester, SMP, PVDF, etc.) may be used depending on the specific requirements.

- The coated steel is then passed through a high-temperature curing or baking process. This solidifies and bonds the coating to the surface of the steel.

- The freshly coated steel is allowed to cool. It is then inspected for uniformity, adhesion, and any potential defects.

- Depending on the specific requirements, an additional clear coat or protective layer may be applied to enhance durability or specific properties.

- After the coating process is complete, the PPGI steel is typically cut into coils or sheets of desired lengths and widths. It is then packaged for storage or shipment.

It's worth noting that the exact details of the coating process may vary depending on the specific manufacturer, type of coating, and quality standards adhered to. Additionally, some manufacturers might incorporate additional steps or specialized treatments for specific applications or enhanced performance.

PPGI (Pre-Painted Galvanized Iron) sheets can come in various thicknesses, typically measured in millimeters (mm). The thickness can range from as low as around 0.1 mm to several millimeters, depending on the specific product and manufacturer. Common thicknesses for PPGI sheets used in roofing and cladding applications are usually between 0.1mm to 1.5 mm. However, it's important to note that the exact thickness can vary depending on the specific requirements of the project and the manufacturer's product offerings.

The price of a PPGI (Pre-Painted Galvanized Iron) color-coated coil can vary significantly depending on several factors, including:

The thickness, width, and length of the coil will greatly influence the price.

2)Coating Type and Thickness

Different coatings (e.g., polyester, SMP, PVDF) and their respective thicknesses will affect the price.

Higher quality coils or those from reputable brands may come at a higher price.

Prices can fluctuate due to supply and demand, as well as global market trends.

Any additional treatments or customization may also impact the price.

Bulk purchases often come with discounts.

7) Location

Prices can vary by region or country due to factors like transportation costs and local market conditions.

For international purchases, currency exchange rates can affect the price.

Deciding between PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) depends on the specific requirements of your project. Both have their own advantages:

PPGI is coated with zinc, providing excellent corrosion resistance. This makes it a good choice for environments where rusting is a concern.

PPGI is often more cost-effective compared to PPGL, making it a popular choice for various applications.

PPGI offers a wide range of colors, allowing for more design flexibility and aesthetic choices.

PPGL is coated with a combination of aluminum and zinc, providing enhanced durability and corrosion resistance compared to PPGI.

PPGL has better heat resistance properties compared to PPGI, which can be advantageous in high-temperature environments.

Due to its enhanced corrosion resistance, PPGL tends to have a longer lifespan compared to PPGI, especially in harsh or corrosive environments.

PPGI Steel Specification

|

Product Name |

PPGI |

|

Standard |

EN10147,EN10142,DIN 17162,JIS G3302,ASTM A663,ISO |

|

Type |

Coil/Sheet/Plate/Strip |

|

Material |

CGCC/SGCH/G350/G450/G550/DX51D/DX52D/DX53D |

|

Thickness |

0.1-1.5mm |

|

Width |

600mm-1500mm |

|

Surface Color |

RAL/Printed/Matte/Wrinkled/Embossed/Nano |

|

Painting Coating |

Top 10-35um,back 7+/-2um |

|

Coating Types |

PE/PVDF/HDP/SMP |

|

Coil Weight |

3tons-8tons |

|

Coil ID |

508mm/610mm |

|

Brand |

Li Cheung |

|

Application |

Purlin,Shutter,Constructions,Chimery,Guardrail,Greenhouse |

|

Zinc Coating |

60-275g/m2 |

|

Grade |

DX51D,DX52D,SGCC |

PPGL Steel Specification

|

Product Name |

PPGL |

|

Standard |

EN10147,EN10142,DIN 17162,JIS G3302,ASTM,A663,ISO |

|

Type |

Coil/Sheet/Plate/Strip |

|

Material |

CGCC/SGCH/G350/G450/G550/DX51D/DX52D/DX53D |

|

Thickness |

0.1-1.5mm |

|

Width |

600mm-1500mm |

|

Surface Color |

RAL/Painted/Matte/ |

|

Painting Coating |

Top 10-35um,back 7+/-2um |

|

Coating Types |

PE/PVDF/HDP/SMP |

|

Coil Weight |

3Tons -8 Tons |

|

Coil ID |

508mm/610mm |

|

Brand |

Li Cheung |

|

Application |

Purlin/Shutter/Constructions/Chimery,Guardrail,/Greenhouse |

|

Azinc Coating |

60-200g/m2 |

|

Grade |

DX51D,DX52D,SGCC |

4) Which is best depends on the specific needs of your project.

If corrosion resistance is a primary concern, especially in environments with high moisture or corrosive elements, PPGL might be the better choice. On the other hand, if cost-effectiveness and a wide range of color options are more important, PPGI could be the preferred option.

It's recommended to consult with a materials expert or supplier who can provide specific recommendations based on the conditions and requirements of your project.

The lifespan of painted galvanized steel, often referred to as PPGI (Pre-Painted Galvanized Iron), depends on several factors including the quality of the coating, the environment it's exposed to, and how well it's maintained.

Under normal conditions, a well-maintained PPGI can last for several decades. In favorable environments, it can even last 20 to 30 years or more. However, in harsher conditions or environments with high levels of moisture, salt, or other corrosive elements, the lifespan may be shorter.

Proper installation, regular inspections, and timely maintenance can significantly extend the life of painted galvanized steel. Additionally, choosing a high-quality coating and following manufacturer recommendations for care and maintenance are important factors in determining the longevity of PPGI.

Keep in mind that while galvanized steel is known for its corrosion resistance, no material is entirely immune to the effects of time and the environment. Regular inspections and maintenance are key to ensuring the longevity of painted galvanized steel.

Pre-painted steel, often referred to as PPGI (Pre-Painted Galvanized Iron) or PPGL (Pre-Painted Galvalume), offers several advantages in various applications:

The galvanized or galvalume coating provides excellent corrosion resistance, extending the lifespan of the steel in various environments.

Pre-painted steel comes in a wide range of colors and finishes, providing design flexibility and allowing for a visually appealing finished product.

PPGI and PPGL are generally more cost-effective than other materials, especially in the long run due to their durability and low maintenance requirements.

Pre-painted steel is typically easier and faster to install compared to materials that require additional finishing processes.

It can be used in a wide range of applications including roofing, siding, appliances, automotive, and more.

The coating process for pre-painted steel is typically more environmentally friendly compared to post-painting methods, as it reduces the release of volatile organic compounds (VOCs).

The pre-applied coating minimizes the need for regular maintenance and repainting, reducing long-term costs.

Pre-painted steel has a consistent and uniform finish across the entire surface, providing a high-quality appearance.

Depending on the specific coating, pre-painted steel can offer enhanced thermal reflectivity, which can contribute to energy efficiency in buildings.

Manufacturers often offer customization options in terms of color, finish, and coating type, allowing for tailored solutions to meet specific project requirements.

The coating provides a protective layer that helps the steel withstand weathering effects, including UV radiation, rain, and snow.

Steel is highly recyclable, making pre-painted steel an eco-friendly choice. It can be recycled without losing its quality.

Overall, the advantages of pre-painted steel make it a popular choice for a wide range of applications in construction, automotive, appliances, and other industries. It combines durability, aesthetics, and cost-efficiency in a versatile material.

The choice between painting and galvanizing depends on the specific application and the priorities of the project. Each method has its own set of advantages and considerations:

Galvanizing provides a high level of corrosion resistance. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rusting.

Galvanized coatings can last for several decades, even in harsh environments, making it a durable option.

Galvanized surfaces require minimal maintenance. They do not need to be repainted or recoated regularly.

The galvanized coating covers the entire surface evenly, providing consistent protection.

Zinc is a natural and recyclable material, making galvanizing an environmentally friendly choice.

Painting offers a wide range of color options, allowing for greater design flexibility and aesthetic customization.

The initial cost of painting is often lower compared to galvanizing.

If a change in color or finish is desired, it's relatively easy to repaint the surface.

Different types of paints can be used to achieve specific properties such as fire resistance, UV protection, or chemical resistance.

Painting allows for intricate designs and detailed graphics.

The environment the material will be exposed to is a critical factor. For highly corrosive environments, galvanizing is often the preferred choice. For aesthetic applications or milder environments, painting may be more suitable.

Initial cost and long-term maintenance should be factored into the decision. Galvanizing may have a higher upfront cost but lower long-term maintenance expenses.

The specific design, color, and finish requirements of the project will influence the choice. Painting offers more customization in terms of aesthetics.

Consider how the material interacts with other components or materials in the project.

Ultimately, there's no one-size-fits-all answer. The choice should be based on a careful evaluation of the specific needs, budget constraints, and environmental conditions of the project. In some cases, a combination of both galvanizing and painting (duplex system) may be used to leverage the benefits of both methods. Consulting with a materials expert or engineer can help in making the most appropriate choice.

To ensure proper adhesion and a long-lasting finish when painting galvanized steel, it's important to follow these steps:

a. Cleaning: Remove any dirt, dust, grease, or contaminants from the surface. This can be done using a mild detergent or a specialized cleaner designed for galvanized surfaces. Rinse thoroughly with water and allow it to dry.

c. Etching: If the galvanized surface is weathered or has a layer of passivation (a naturally occurring film on the surface), it may be necessary to etch it with an acid solution. A phosphoric acid-based etching solution is commonly used. Follow manufacturer instructions for application and rinsing.

b. Apply Primer: Apply a thin, even coat of primer to the galvanized surface. Allow it to dry according to the manufacturer's recommendations.

c. Sand or Scuff (Optional): In some cases, especially if the galvanized coating is very smooth, lightly sanding or scuffing the surface after priming can improve adhesion.

a. Choose the Right Paint: Use a high-quality paint that is suitable for use on galvanized steel. Acrylic-based or epoxy-based paints are commonly used.

b. Apply Paint: Apply the paint in thin, even coats. Allow each coat to dry before applying the next. Follow the manufacturer's instructions regarding drying times and the recommended number of coats.

After painting, allow the final coat to cure for the recommended time before subjecting it to any stress or environmental conditions.

Remember to work in a well-ventilated area and use appropriate personal protective equipment, especially when working with cleaning agents and paints. Additionally, always follow the specific instructions provided by the manufacturer of the cleaning agents, primers, and paints you are using.

For painting galvanized steel, it's recommended to use a paint that is specifically formulated for use on this type of surface. Here are some types of paint that are commonly used for galvanized steel:

2)Epoxy-Based Paints: Epoxy paints are known for their excellent adhesion and chemical resistance. They can be a good choice for galvanized steel in industrial or corrosive environments.

5) Zinc-Rich Paints: These paints contain a high concentration of zinc and are specifically designed for application on galvanized steel. They provide an extra layer of protection against corrosion.

When choosing a paint, make sure to verify that it is compatible with galvanized steel and follow the manufacturer's recommendations for surface preparation and application. Additionally, consider the specific conditions the painted surface will be exposed to (e.g., outdoor exposure, chemical exposure) to select a paint with the appropriate level of durability and resistance.

Always ensure that you work in a well-ventilated area and use the appropriate personal protective equipment when handling paints and related chemicals.

Several types of coatings are used in various industries for protection, aesthetics, or specific functionalities. Here are some common types:

- Acrylic Paint: Fast-drying and versatile, used for a wide range of applications.

- Epoxy Paint: Known for its excellent adhesion and chemical resistance, used in industrial settings.

- Polyurethane Paint: Provides high durability and is resistant to weathering, commonly used in outdoor applications.

- Alkyd Paint: Oil-based paint known for its durability and adhesion to metal surfaces.

- Hot-Dip Galvanizing: A layer of zinc is applied to steel through a hot-dip process, providing excellent corrosion resistance.

- Electro-Galvanizing: Zinc is electroplated onto the steel surface, offering similar corrosion protection as hot-dip galvanizing.

- Aluminum Paint: Contains aluminum flakes for a metallic finish and corrosion resistance.

- Anodizing: An electrochemical process that forms a layer of oxide on aluminum, enhancing corrosion resistance and providing a decorative finish.

- Zinc-Rich Paint: Contains a high concentration of zinc for added corrosion protection.

- Thermosetting Powder Coating: Applied as a dry powder, then cured under heat. Offers a durable finish and is commonly used on metals, plastics, and ceramics.

- Thermoplastic Powder Coating: Unlike thermosetting, thermoplastic coatings can be melted and re-solidified multiple times.

- Polyethylene Coating: Used for corrosion protection of pipelines and similar applications.

- Polyurea Coating: Offers high abrasion resistance and is commonly used for protective coatings.

- Thermal Barrier Coatings: Used in high-temperature applications to protect against heat and corrosion.

- Non-Stick Ceramic Coatings: Used in cookware and other applications where non-stick properties are desired.

- Zinc Phosphate: Provides corrosion resistance and is used as a base for paints and coatings.

- Decorative Chrome Plating: Provides a shiny, decorative finish on various materials.

- Hard Chrome Plating: Offers wear resistance and corrosion protection.

- Electroless Nickel Plating: Provides corrosion resistance and wear resistance.

- PTFE (Polytetrafluoroethylene): Known for its non-stick properties, used on cookware, industrial equipment, and more.

These are just some of the many types of coatings available, each with its own specific properties and applications. The choice of coating depends on factors such as the material being coated, the environment it will be exposed to, and the desired outcome (corrosion resistance, aesthetics, etc.).

After galvanizing steel, it's important to allow sufficient time for the surface to weather or "age" before painting. This allows the zinc coating to fully stabilize, ensuring proper adhesion of the paint.

Typically, it is recommended to wait a period of **4 to 6 months** before painting newly galvanized steel. During this time, natural weathering processes, including exposure to air and moisture, help the surface achieve optimal conditions for paint adhesion.

However, if the galvanized surface has been treated with passivation solutions or coatings by the galvanizing plant, it may require less time before painting. In such cases, you should consult with the galvanizing plant or a coatings specialist for specific recommendations.

Remember that surface preparation is crucial for a successful paint application on galvanized steel. This may involve cleaning, degreasing, etching (if necessary), and applying an appropriate primer before painting. Always follow the manufacturer's recommendations for surface preparation and paint application.

Certainly! When looking for technical details of PPGI (Pre-Painted Galvanized Iron) steel coils from a Chinese manufacturer, you may find information like the following:

1)Material Type:

PPGI coils are typically made from hot-dip galvanized steel or galvalume steel.

2)Coating Type and Thickness:

Details about the type of coating used (e.g., polyester, SMP, PVDF) and their respective thicknesses.

The weight of the coating is often specified in grams per square meter (g/m²) or ounces per square foot (oz/ft²).

The thickness of the underlying steel is typically measured in millimeters (mm) or inches (in).

Specifications regarding the width and length of the PPGI coils.

The weight of the entire coil, including both the steel and the coating, is usually specified in kilograms (kg) or pounds (lb).

Information about the combination of coatings used, including details about the type of primer, topcoat, and back coat.

This is a measure of how much force the steel can withstand before it starts to deform. It is usually specified in megapascals (MPa) or pounds per square inch (psi).

This is the amount of stress at which the steel begins to deform plastically. It is also specified in megapascals (MPa) or pounds per square inch (psi).

Details about the intended application of the PPGI coils, such as roofing, siding, automotive parts, appliances, etc.

Information regarding any certifications or quality standards the PPGI coils adhere to, such as ISO, ASTM, or specific industry standards.

Information about the available color options for the PPGI coils.

Please note that these details can vary between different manufacturers and product lines. It's recommended to contact the specific Chinese manufacturer for the most accurate and up-to-date technical specifications of their PPGI steel coils.

PPGI (Pre-Painted Galvanized Iron) steel wire is not inherently fireproof. While the galvanized coating provides some level of fire resistance due to the non-combustible nature of zinc, it does not make the wire completely fireproof.

In the event of exposure to high temperatures or fire, PPGI steel wire will eventually begin to melt and deform like any other steel product. It is important to note that the fire resistance of any material, including PPGI steel, depends on various factors such as the intensity and duration of the fire.

Suppose fire resistance is a critical factor for a specific application. In that case, it is recommended to consult with a materials expert or refer to fire safety standards and regulations to select a material that meets the required fire resistance criteria. Additionally, using specialized fire-resistant coatings or treatments may be necessary to enhance the fire resistance of the steel wire.

The HS code for PPGI (Pre-Painted Galvanized Iron) steel varies depending on the specific characteristics and composition of the product. Generally, PPGI steel falls under HS code 721070, which covers flat-rolled products of iron or non-alloy steel, plated or coated with zinc. However, for precise classification and customs purposes, it's advisable to refer to the official customs documentation or consult with a trade expert familiar with the specific regulations of the country in question.

The latest news update as of September 2021 is that China offers export tax rebates on certain products, including steel products such as steel and PPGI (pre-coated galvanized iron). These tax rebates are part of China's export policy to promote trade and support certain industries.

Li Cheung Steel Factory Advantage 1:

PPGI does not lose paint during use

Inventory is sufficient during the peak sales season because the factory production line has never stopped production

the received PPGI will not be affected by moisture and oxidation, because the packaging is very strict

and our steel is fire-resistant

Li Cheung Steel Co., LTD

Since its inception in 2005, Li Cheung Steel Factory has grown to become the largest manufacturer of GI PPGI steel in China. An ISO 9001-certified company.

Professional team

29,000+ experts worldwide

Senior project managers effectively control all aspects of the project

7x24 hours delivery

Located in 27 cities around the world, with 50 delivery centers, providing 200+ languages, and 7x24 hours delivery capacity, is the best partner for enterprise globalization

Let's Read the Brief introduction of the writer about the text first

𝗪𝗵𝘆 I am 𝗮 𝗪𝗼𝗿𝗸𝗮𝗵𝗼𝗹𝗶𝗰?

Why I am a workaholic is not well understood. I do feel that in this GI ,PPGI ,GL ,Roofing Sheet job customers give me great trust, I have the opportunity to serve. As 1 service provider. What I gain is the trust from everyone. You see so many steel factories, still many people come to Li Cheung Steel Factory, I want to cherish this opportunity to bring value and service to customers.

Now I am 28 years old. I have gone this job for 4 years and believe I am quite experienced in this field. To serve our clients better and get trusted,I spend a lot of time learning from our engineers and technical team.Quality is the true reason that we survive in the market for so many years.

I am a very very enthusiastic person and I am very very glad to help you if I have any chance. If you have GI, PPGI, GL, PPGL , Roofingsheet steel industry confusion, or If you have steel internet marketing questions, or 2024 a direction, or you have ideas to make investments in 2024, or you are making adjustments, you're not quite clear, welcome to come to Li Cheung Steel Bella for advice as soon as possible.

If you need steel welcome to contact us!

Email: sales@licheungsteel.com

WhatsApp:+86 132 1317 8890

http://wa.me/8613213178890