Coil ID: 508 mm - 610 mm

Coil weight: 3 - 8 ton or as client requirement.

Zinc coating: 30g - 275g / m2

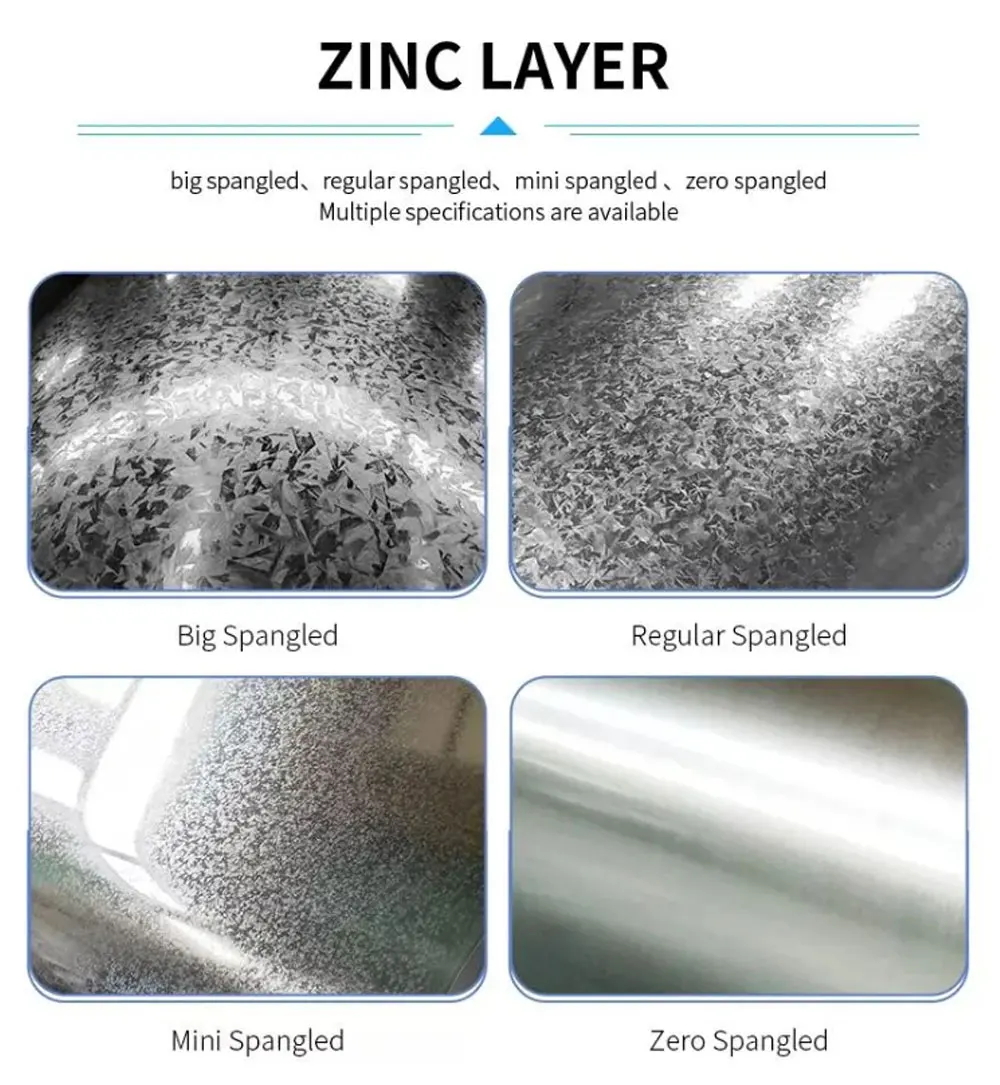

Spangle: Big spangle,Regular spangle,Mini spangle,Zero spangle

Surface treatment: Oil,Passivation, Chromated, Skin-passed, Anti-finger Print

SGCC steel is hot-dip galvanized steel coils and sheets that comply with JIS G3302 standards. It has excellent durability and corrosion resistance. The thickness of SGCC materials ranges from 0.20 mm to 3.5 mm. If you are interested in learning more about State Grid Steel, please feel free to contact us.

SGCC material is commercial quality hot-dipped galvanized steel. The first letter "S" stands for steel, while the "G" stands for galvanized. The third letter "C" refers to cold rolled steel. That is, the base material is CR steel. The fourth letter "C" stands for commercial quality. Equivalent to DX51D material in EN 10327 standard.

It is important to note that SGCC is the standard designation in the industry and the specific properties of SGCC steel may vary depending on the manufacturing process and the intended use of the material. If you require more details on a specific SGCC steel product, please contact Li Cheung Steel

SGCC steel finds widespread applications across various industries due to its excellent corrosion resistance properties resulting from the cold galvanizing process. Commonly used in construction, automotive manufacturing, and electrical appliances, SGCC steel provides durable and long-lasting protection against rust and corrosion. In construction, it is employed for structural components and roofing materials, ensuring the longevity of buildings in diverse environmental conditions. In the automotive industry, SGCC steel is utilized in the manufacturing of vehicle bodies, frames, and other components to enhance resistance to the corrosive effects of road conditions and weather exposure. Additionally, its corrosion-resistant qualities make it suitable for use in the production of electrical appliances, such as refrigerators and washing machines. The versatility and protective features of SGCC steel make it a preferred material in applications where durability and resistance to corrosion are essential.

SGCC Steel Hot Dip Galvanized Steel -JIS G3302 Advantage

1) Excellent corrosion resistance

2) Strong weather resistance

3) Bright surface and beautiful appearance

4) Easy to process

5) Economical solution

| Item | C | Mn | P | S | Yield strength | Tensile strength | Hardness |

| SGCC | ≤0.15% | ≤0.8% | ≤0.05% | ≤0.05% | ≥205 MPa | ≥270 MPa | 60 HRb |

SGCC (Steel Grade Cold Galvanized Commercial) and SECC (Steel Grade Electrolytic Galvanized Commercial) are both designations for galvanized steel, but they differ in terms of the galvanization process used and, consequently, their applications.

1. Galvanization Process:

- SGCC: This steel undergoes cold galvanization, where the steel is immersed in a zinc bath at low temperatures. The process creates a protective zinc coating on the steel surface, providing corrosion resistance.

- SECC: In contrast, SECC steel undergoes electrolytic galvanization, which involves passing an electric current through a zinc solution where the steel is submerged. This results in a more controlled and precise zinc coating.

2. Surface Appearance:

- SGCC: Cold galvanization often produces a spangled or crystalline surface appearance on the steel, which can vary in size and pattern.

- SECC:Electrolytic galvanization typically results in a smoother and more uniform zinc coating on the steel surface.

3. Applications:

- SGCC:Commonly used in general applications such as construction, automotive manufacturing, and appliances where corrosion resistance is essential.

- SECC:Often preferred for applications where a more refined and aesthetically pleasing surface finish is desired, such as in the production of electronic enclosures and components.

4. Cost:

- SGCC:Generally, cold galvanization is considered more cost-effective than the electrolytic galvanization process used for SECC.

In summary, while both SGCC and SECC are galvanized steels, the differences lie in the galvanization process, resulting surface appearance, and specific applications. SGCC is more commonly used in general industries, while SECC, with its smoother surface finish, is often chosen for applications where appearance matters, such as in electronics.

| SGCC | SECC | |

| Formability | Average | Good |

| Paintability | Average | Good |

| Corrosion resistance | Excellent | Average |

| Appearance | Rough and bright | Smooth and dull |

SGCC steel coils and plates are available in a variety of thicknesses, ranging from 0.1 mm to 3.0 mm. Additionally, galvanized layer thickness ranges from 30-275 g/m2. As one of the largest galvanized steel suppliers in China, Li Cheung Steel offers hot-dip galvanized and electro-galvanized steel coil, plate and strip products, all of which comply with different industry standards. Welcome to contact us for more details!

Hot Tags: sgcc steel hot dip galvanized steel -jis g3302, manufacturers, suppliers, factory, price, for sale, china steel coil, gi steel coil, hot dipped galvanized steel coils, hot dip galvanised steel, hot dip galvanized steel, galvanizing plant