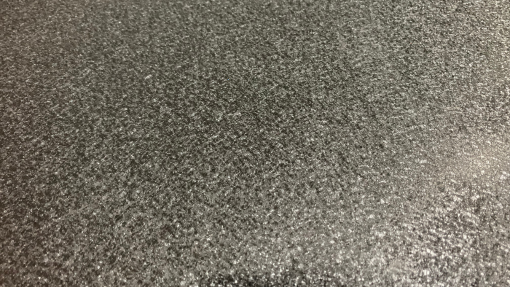

Spangle: Zero/Regular/Small/Big Spangle

Zinc Coating: Z30-Z275

Thickness: 0.1-3.0mm

MOQ: 25MT

Quality: High-Quality Inspection

DX53D steel is a low-carbon steel classified under the EN 10346 standard, specifically designed for applications requiring good formability and corrosion resistance. It is primarily used in the automotive and construction industries due to its excellent deep drawing capabilities.

| Product | dx53d steel |

| Standard | AiSi, ASTM, bs, DIN, GB, JIS |

| Material | SGCC,DX51D,etc |

| Technique | Cold Rolled |

| MOQ | 25MT |

| Surface Treatment | Galvanized, Coated |

| Painting | PE, SMP, HDP, PDVF |

| Tolerance | ±1% |

| Certificate | ISO9001 |

| Quality | High-Quality Inspection |

| Packing | Standard Seaworthy Package |

| Thickness | 0.1-3.0mm |

| Coating | Z30-Z275 |

| Spangle | Zero/Regular/Small/Big Spangle |

| Sample | Free Samples Available |

| Payment Terms | T/T, L/C |

| Loading Port | Qingdao/Tianjin Port |

| Delivery Time | Within 20-30 Days |

Standards: Manufactured according to various standards, such as ASTM A653 and EN 10346.

Inspection: Quality checks for coating thickness, adhesion, and surface defects are standard practice.

Mini Spangle

Regular Spangle

Big Spangle

GI Sheet Packed

Load into container

Testing equipment

Storage Conditions

Should be kept in a dry environment to prevent moisture accumulation.

Care in Handling

To avoid scratches and damage to the zinc coating, proper handling techniques are essential.

A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

A: It takes about 10 days to stock goods, or it will need 15-25 days if goods need to be customized.

A: We are galvanized steel coil manufacturers. We have our own factory and sales team. Welcome to seeing and inspecting our factory.

A:Yes,we have ISO,BV,SGS Ceritifications and our own quality contorl laboratory.

A: T/T, L/C, PayPal.

A: The surface treatment of our galvanized coils has big spangle, small spangle, zero spangle and regular spangle according to customer needs.

Hot Tags: dx53d steel, manufacturers, suppliers, factory, price, for sale, ppgi steel, pre painted corrugated gi sheet, coil galvalume, color coated galvanized steel coil, gi roofing sheet, prepainted steel coil