DX51D Q195 Z30-275 Hot Dipped GI/Material:SGCC/Q195/Q235/TDC51DZM/TDC52DTS350GD/Zinc coating:30-275g/m2

Technical Parameters

| Commodity | DX51D Q195 Z30-275 Hot Dipped GI |

| Thickness | 0.12mm-1.5mm |

| Width | 250mm-1500mm |

Zinc coating | Z30-Z275 g/m2 |

| Coil ID | 508/610mm |

| Weight | 3-6MT Per Coil |

| Spangle | Regular/zero/small/big spangle |

| Special Use | High-strength Steel Plate |

Shape | Flat. Sheet. Coil |

Supply capacity | 4000 MT Per month |

Application | Industrial panels, roofing and siding for painting |

| PPGI Base plate | |

| Various roofs and walls referring to the large size factory buildings | |

| MOQ | 1*20GP FCL |

Treatment | Chromate Acid |

| Loading Port | Any Port in China |

Product images

Pictures of the product of DX51D Q195 Z30-275 Hot Dipped GI.

DX51D Q195 Z30-275 Hot Dipped GI process: finished pickling-washing-assisting plating-drying-hanging-cooling-pharmaceutical-cleaning-grinding-hot galvanizing is completed. Hot-dip galvanizing is a result of the older hot-dip method. Since the application of hot-dip galvanizing in France in 1836, it has been more than 170 years old. In the past three decades, with the rapid development of cold-rolled strip, the hot-dip galvanizing industry has been developed on a large scale.

DX51D Q195 Z30-275 Hot Dipped GI is mainly used in industrial products. The DX51D Q195 Z30-275 Hot Dipped GI layer is generally above 35μm, the standard requirement is about 80μm, some even up to 200μm, the covering ability is good, the coating is dense, and even in the years and years, even if it is damaged by oxidation, Constantly indicating the formation of protective film, and constantly protecting the inside, mainly used in various line fittings or important persistent industrial products. The electroplated layer is more uniform than the hot dip layer and is generally thin, ranging from a few microns to tens of microns. Through electroplating, decorative protective and various functional surface layers can be obtained on mechanical products, and workpieces with wear and processing errors can be repaired. The electro-galvanized layer is thinner, mainly to enhance the corrosion resistance of the metal (the coating metal is mostly used). Corrosion-resistant metal), increase hardness, prevent wear, improve electrical conductivity, smoothness, heat resistance and surface appearance. Mainly used in a variety of decorations or luxury goods.

What We Can OFFER

Li Cheung Steel Co., Ltd main export product as below image:

GI/GL/PPGI/PPGL/PPCR/CR/Nano Anti-corrosion Sheet/Roofing sheet/Strips/Tinplate.

Our Factory

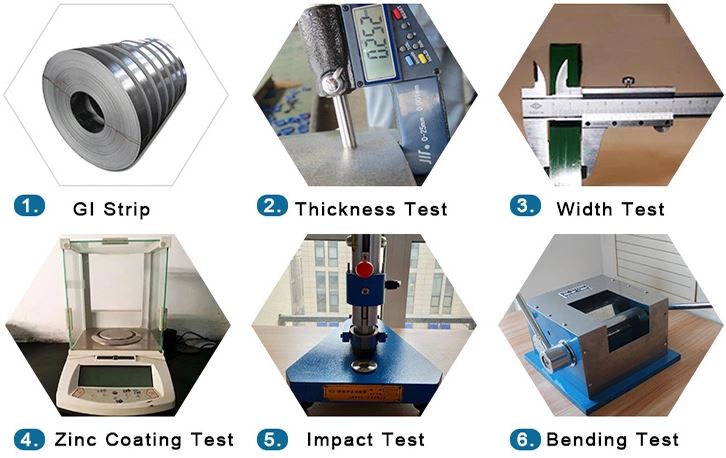

Quality Inspection

Professional and rigorous detection of Specific Projects as follow:

HRB hardness test+glossiness test+coating adhesion test+bending test+impact test

+zinc coating test+compression test+salt spray test+MEK resistance test

Contact us

Hot Tags: dx51d q195 z30-275 hot dipped gi, manufacturers, suppliers, factory, price, for sale, gi coil, galvanizing plant, hot dipped galvanised coil, hot dip galvanizing plant, hot dipped galvanized steel coils, cold rolled steel sheet in coil