Li Cheung Steel Factory from a Chinese Company, and Iron &steel aluminum supplier. Li Cheung Steel was established back to 20 years ago and we often cooperate with 500 well-known Steel factories in the world . More importantly, and we follow those local projects, the government project Li Cheung Steel is very professional. Jainhui Steel has been in this steel industry for 20 years. We know every single detail about this industry about this galvalume product. We are pretty sure we can be reasonable and responsible and professional on this deal.

Galvanized steel is steel that has been coated with a layer of zinc to help prevent corrosion. The process of galvanization involves applying a protective zinc coating to the steel to create a barrier between the metal and the surrounding environment. This coating acts as a sacrificial anode, meaning that it corrodes before the underlying steel does, providing extended protection against rust and other forms of corrosion.

The galvanization process typically involves immersing the steel in a bath of molten zinc or using a process known as hot-dip galvanizing. Alternatively, electroplating can be used to apply a thinner layer of zinc to the steel. This protective zinc layer gives galvanized steel its characteristic silver-gray appearance.

Galvanized steel is commonly used in a variety of applications where corrosion resistance is essential, such as in construction, automotive manufacturing, and outdoor structures. It is particularly valued for its durability and ability to withstand harsh environmental conditions.

|

Product Name |

Hot dip DX51D Z100 galvanized steel coil |

|

Width |

600mm-1500mm, according to customer's requirement |

|

Thickness |

0.3 ---3.0mm |

|

Galvanized Weight |

30g/m2--275g/m2 |

|

Standard |

EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

|

Steel grade |

Dx51D/Dx52D/Dx53D/DX54D/S250GD/S350GD/S550GD |

|

Applications range |

home appliance,building material, machinery,roofing sheet,etc. |

|

MOQ |

25 tons |

|

Quality |

approved by SGS |

|

Authentication |

ISO9001:2008 |

|

Market |

North/South America, Europe, Asia,Africa,Mid East,ect. |

|

Packaging |

water proof paper is inner packing, galvanized steel or coated steel sheet is outer packing , side guard plate , then wrapped by |

|

Port |

Qingdao, Tianjin |

|

Delivery time |

In 10-25 days after receipt of deposit or L/C,T/T |

|

Type |

Hot-Galvanized Steel Sheet |

|

Processing Service |

Bending, WELDING, Decoiling, Cutting, PUNCHING |

|

Product name |

galvanized steel coil |

|

Payment Term |

TT/LC |

PPGI stands for "Pre-Painted Galvanized Iron" or "Pre-Painted Galvanized Steel." It refers to galvanized steel that has been coated with a layer of paint or another coating before being formed into the final product. This pre-painting process provides additional protection against corrosion and enhances the aesthetic appeal of the steel.

The PPGI coating is typically applied using a coil coating process, where the steel coil is continuously coated with paint in a controlled environment. This allows for a uniform and durable finish. The coatings used on PPGI steel can include a variety of materials, such as polyester, polyvinylidene fluoride (PVDF), or plastisol, depending on the desired characteristics and the intended application.

PPGI steel is widely used in the construction industry for roofing, siding, and other architectural elements. The pre-painted coating not only adds a decorative finish but also provides an extra layer of protection against the elements. Additionally, PPGI is used in the manufacturing of appliances, automotive components, and other products where a combination of corrosion resistance and aesthetic appeal is important.

|

Technical Standard |

EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

|

|

DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, |

|

Base Steel |

Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

|

Thickness |

0.12-6.0mm |

|

Width |

600-1500mm |

|

Surface Color |

RAL,wood grain pattern, camouflage pattern , stone pattern, matte pattern , high gloss pattern , flower pattern, etc |

|

Quality |

Approved by SGS,ISO |

|

Coil Weight |

3-20metric ton per coil |

|

|

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by |

|

Export market |

Europe,Africa,Central Asia,Southeast Asia,Middle East,South America,North America, etc |

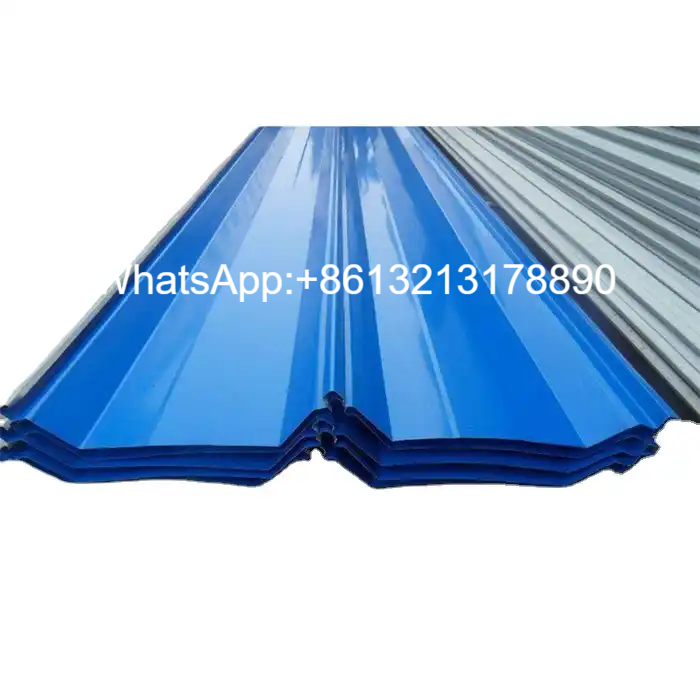

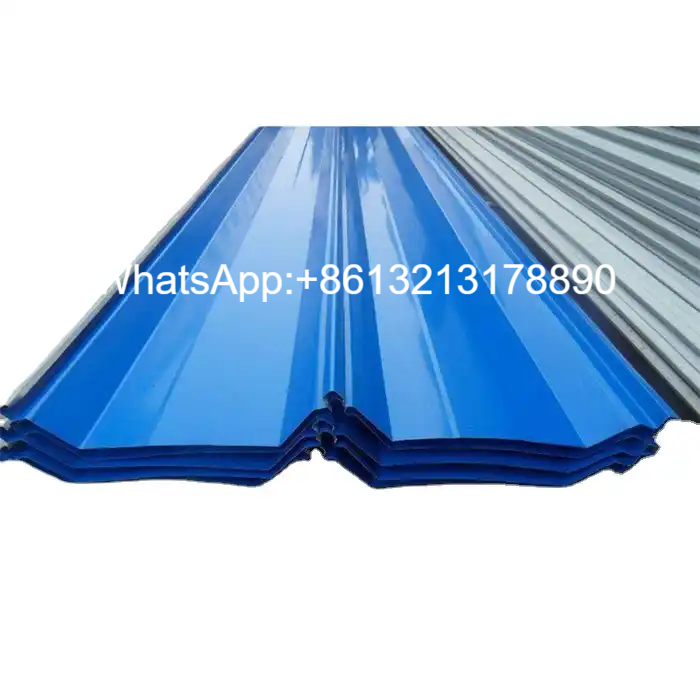

CGI stands for "Corrugated Galvanized Iron" or "Corrugated Galvanized Steel." It refers to a specific type of galvanized steel that has been formed into sheets with a corrugated or wavy pattern. The corrugation not only adds strength to the sheet but also provides channels for water runoff, making CGI steel particularly suitable for roofing applications.

The process of creating CGI steel involves passing flat sheets of galvanized steel through a series of rollers that shape the material into the characteristic corrugated pattern. The galvanized coating on the steel provides protection against corrosion, making CGI a durable and long-lasting material.

CGI steel sheets are commonly used for roofing in a variety of structures, including residential homes, industrial buildings, and agricultural facilities. The corrugated design enhances the strength of the material while allowing for efficient water drainage. Additionally, CGI steel is used for siding and cladding applications, providing both functional and aesthetic benefits. The galvanized coating contributes to the overall corrosion resistance of the material, making it suitable for outdoor use in different climates.

|

Products name |

ASTM A653 prepainted metal galvanized steel corrugated roofing sheets |

|

Capacity |

about 15000 tons per month for the steel sheet and coil product |

|

Standard |

ASTM A653 |

|

Thickness |

0.12-0.3mm |

|

Width |

800mm-900mm |

|

Zinc coating weight |

40g/m2-275g/m2, double side |

|

Surface coating |

PE, SMP, HDP, PVDF |

|

Top side |

15-25 um |

|

Back side |

5-8 um |

|

Yield strength |

250~600 MPa |

|

Tensile strength |

350~800 MPa |

|

Size Tolerance |

± 1%~3% |

|

Color |

All RAL/TN colors |

|

Edge |

mill edge cut edge |

|

Payment terms |

L/C at sight,30%T/T ,70% balance against B/L copy,Alibaba Trade Assurance |

|

Packing |

Mill's standard export sea-worthy packing |

|

Delivery Time |

7-15 days after receiving payment |

|

Application |

Construction, roofing |

|

Remarks |

The third-party inspection is accepted |

1)What are the advantages of using galvanized steel coils?

Galvanized steel coils offer several advantages, including excellent corrosion resistance, durability, and a long lifespan. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and other forms of corrosion. This makes galvanized steel coils suitable for outdoor and harsh environments.

2)Where are galvanized steel coils commonly used?

Galvanized steel coils find widespread use in various industries. Common applications include construction (roofing, siding, and structural components), automotive manufacturing, appliances, and agricultural equipment. The corrosion resistance and strength of galvanized steel make it versatile for both indoor and outdoor applications.

3)Can galvanized steel coils be painted?

Yes, galvanized steel coils can be painted. However, for applications where a specific color or additional protection is desired, pre-painted galvanized steel coils (PPGI) are often used. These coils undergo a painting process before being formed into the final product, providing both aesthetic appeal and an extra layer of protection against corrosion

4)How do I maintain galvanized steel coils?

Galvanized steel is known for its low maintenance requirements. Regular cleaning to remove dirt and debris is usually sufficient. In cases where the zinc coating may get damaged, touch-up coatings or zinc-rich paints can be applied to maintain the protective layer.

5)What are the environmental benefits of galvanized steel coils?

Galvanization is considered an environmentally friendly process. The use of zinc as a coating material is non-toxic, and it can be recycled. Additionally, the longevity of galvanized steel reduces the need for frequent replacements, contributing to resource conservation.

1) What is PPGI coil used for?

- PPGI coils are commonly used in the construction industry for roofing, siding, and other architectural applications. The pre-painted coating enhances the aesthetic appeal and provides an additional layer of protection against corrosion. They are also used in manufacturing appliances and automotive components.

2) How is the paint applied to PPGI coils?**

- The paint is applied to PPGI coils through a coil coating process. In this method, the steel coil is continuously coated with paint in a controlled environment. This ensures a uniform and durable finish on the entire surface of the coil.

3)What types of paint coatings are used on PPGI coils?**

- Various types of paint coatings can be used on PPGI coils, including polyester, polyvinylidene fluoride (PVDF), or plastisol. The choice of coating depends on factors such as the desired level of durability, weather resistance, and the intended application of the PPGI steel.

4)Is PPGI coil environmentally friendly?**

- PPGI coils can be environmentally friendly, especially if the paints used are low in volatile organic compounds (VOCs). Additionally, the long lifespan and corrosion resistance of PPGI steel contribute to its sustainability by reducing the need for frequent replacements.

5)Can PPGI coil be customized in terms of color and design?**

- Yes, PPGI coils offer a high degree of customization in terms of color and design. Manufacturers can provide a wide range of colors to meet specific aesthetic requirements, and the pre-painting process allows for the application of different designs and patterns according to the customer's preferences.

What is CGI steel used for?

CGI steel is commonly used for roofing in residential, industrial, and agricultural buildings. The corrugated pattern adds strength to the sheets and facilitates efficient water drainage, making it suitable for various outdoor applications. Additionally, CGI is used for siding and cladding.

How is CGI steel manufactured?

CGI steel is produced by passing flat sheets of galvanized steel through a series of rollers that shape the material into a corrugated pattern. The galvanization process involves applying a layer of zinc to protect the steel from corrosion.

What are the advantages of using CGI steel for roofing?

CGI steel offers several advantages for roofing, including high strength due to its corrugated pattern, effective water runoff, and resistance to corrosion. The galvanized coating provides additional durability, making it a popular choice for a wide range of structures.

Is CGI steel environmentally friendly?

The galvanization process, which involves applying a zinc coating to the steel, can be considered environmentally friendly because it enhances the longevity of the material, reducing the need for frequent replacements. Additionally, steel is recyclable, contributing to sustainability.

Can CGI steel be painted or coated for additional protection?

While CGI steel already has a galvanized coating for corrosion resistance, it can be further painted or coated with additional protective layers if desired. This customization allows for enhanced durability and can also be done for aesthetic reasons in certain applications.

|

Commodity |

Color Coated Ppgi Ppgl Steel Sheet Corrugated Roofing Tile |

|||

|

Base Steel |

Galvanized Steel |

Galvalume Steel |

PPGI |

PPGL |

|

Thickness(mm) |

0.13-1.5 |

0.13-0.8 |

0.13-0.8 |

0.13-0.8 |

|

Width(mm) |

750-1250 |

750-1250 |

750-1250 |

750-1250 |

|

Surface Treatment |

Zinc |

Aluzinc Coated |

RAL Color Coated |

RAL Colorcoated |

|

Standard |

ISO,JIS,ASTM,AS,EN |

|||

|

Width(mm) |

610-1250mm |

|||

|

Color Coating(Um) |

Top:5-25m Back:5-20m or as client's requirement |

|||

|

Paint Color |

RAL code No.or customer' color sample |

|||

|

Pallet Weight |

2-5MT or as client's requirement |

|||

|

Quality |

Softy , half hard and hard quality |

|||

|

Supply Ability |

2000-5000MT/month |

|||

|

Price Item |

FOB, CFR, CIF |

|||

|

Payment terms |

T/T, L/C at sight |

|||

|

Delivery Time |

15-35days after confirmed order |

|||

|

Packaging |

Export standard, seaworthy |

|||

In conclusion, galvanized steel, whether in the form of PPGI (Pre-Painted Galvanized Iron/Steel) or CGI (Corrugated Galvanized Iron/Steel), represents a versatile and durable material with enhanced corrosion resistance. Galvanized steel undergoes a process where a protective layer of zinc is applied, forming a barrier against rust and corrosion. PPGI adds an extra layer of protection through pre-painting, offering not only durability but also aesthetic appeal, making it suitable for various applications in construction, automotive manufacturing, and more. On the other hand, CGI, with its corrugated pattern, is often employed in roofing and siding due to its strength, efficient water runoff properties, and resistance to corrosion. Both PPGI and CGI showcase the adaptability and reliability of galvanized steel across a range of industries and applications.

Hot Tags: gi&ppgi&cgi steel, manufacturers, suppliers, factory, price, for sale,