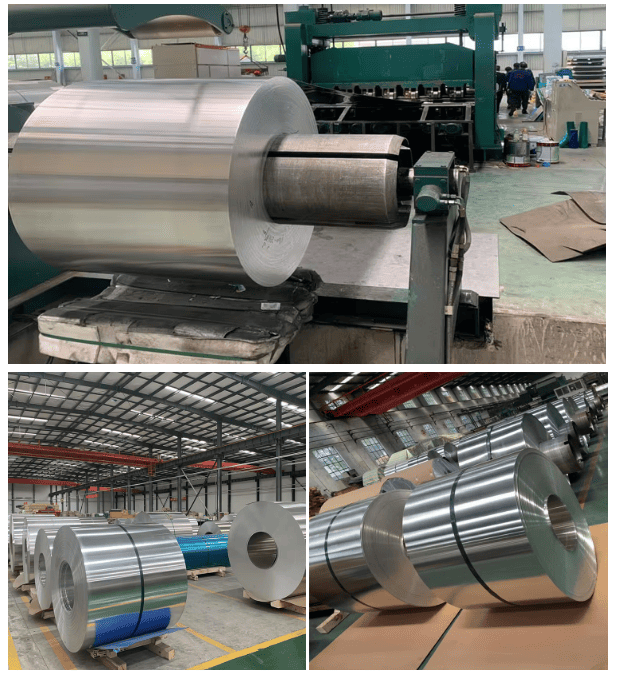

Surface: Embossed, Mill finish, Coated

Painting: PE / PVDF /Powder painted

Weight: 2.0-3.0 Tons/coil

Delivery Time: Within 20-30 Days

Quality: High-Quality Inspection

Aluminum coil stock can be further processed into various forms, such as sheets, strips, or custom shapes. It can undergo additional treatments like anodizing, painting, or coating to enhance its properties or appearance.

Aluminum coil stock is a fundamental material in modern manufacturing and construction, offering a combination of strength, durability, and lightweight characteristics. Its versatility allows it to be used in a wide range of applications, making it an essential component in many industries. Whether for construction, automotive, or packaging, aluminum coil stock provides a reliable solution that meets diverse needs.

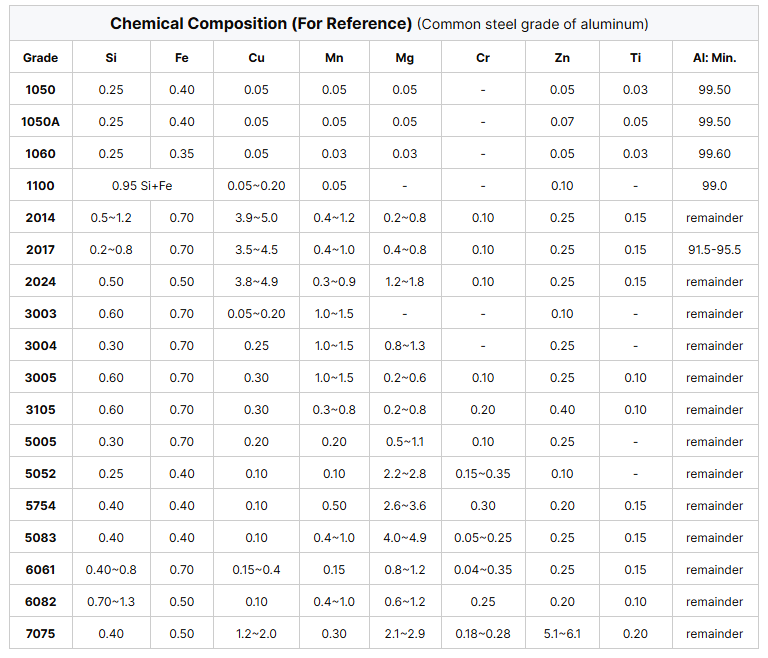

| Product | Aluminum coil stock |

| Alloy |

1050/1060/1100/3003/3004/5005/5052/5083/3005/8011 |

|

Temper |

H12, H16, H18, H24, H26, H44 |

| Material |

SGCC, SGCH, Q195, Q235, DX51D |

|

Surface |

Embossed, mill finish, coated |

| Painting | PE / PVDF /Powder painted |

| Tolerance | ±1% |

| Certificate | ISO9001 |

| Quality | High-Quality Inspection |

| Packing | Standard Seaworthy Package |

| Sample | Free Samples Available |

| Payment Terms | T/T, L/C |

| Loading Port | Qingdao/Tianjin Port |

| Delivery Time | Within 20-30 Days |

1

2

3

Casting and Rolling

Aluminum ingots are melted and cast into slabs, which are then hot-rolled into thicker sheets. These sheets are further processed by cold rolling to achieve the desired thickness and properties.

Coiling

The rolled aluminum sheets are then coiled into rolls, which can vary in diameter and weight based on customer specifications.

Quality Control

Manufacturers perform rigorous quality checks throughout the process to ensure consistency in thickness, strength, and surface finish.

A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

A: It takes about 10 days to stock goods, or it will need 15-25 days if goods need to be customized.

A: We are galvanized steel coil manufacturers. We have our own factory and sales team. Welcome to seeing and inspecting our factory.

A:Yes,we have ISO,BV,SGS Ceritifications and our own quality contorl laboratory.

A: T/T, L/C, PayPal.

A: The surface treatment of our galvanized coils has big spangle, small spangle, zero spangle and regular spangle according to customer needs.

Hot Tags: aluminum coil stock, manufacturers, suppliers, factory, price, for sale, color coated galvanized steel coil, ppgi roofing sheet, color steel coil, china steel coil, ppgl steel, pre painted steel sheet

←No Information